Environment Dimension

The company is committed to conducting business in harmony with the environment and social responsibility, including management to reduce greenhouse gas problems. It has set environmental goals and strives to maintain and develop the management system continuously to achieve standard quality.

Environmental Management

Ratch Pathana Group & Affiliates have defined environmental objectives committed to continual develop the environmental management system to ensure the effectiveness and meet the internaltional standard, as well as running business with environmental and social responsibility.

Water Management

Ratch Pathana Group places the importance of the effective water management throughout all production processes, from the source of water for production input until the preservation of the environment after production process. The company therefore strictly adheres to regulations of water management and considers the impacts of water consumption to the nearby communities. On the other hand, Ratch Pathana Group also plans to prevent the risk of water shortage which may interrupt the power plant operations.

Key Performance

Target for Reducing Raw Water use in the Energy Production Process in 2023

Air Emission Management

Strictly implement air pollution management measures as follows:

- The emission monitoring system is installed at the stacks of the power plant for measuring the amount of TSP, SO2 , and NO2 emitted to the atmosphere. The results indicated that the amounts of those pollutants are within the legal limits.

- Installed the emission monitoring system in the communities’ area nearby the power plant, composing environmental monitoring reports in every 6 months for the related sectors and public to ensure that the air qualities are according to the standards and regulations.

- The Electrostatic Precipitators (ESP) with 99.5% of particulate-collecting efficiency was installed at the biomass power plant of Sahacogen Green and Sahagreen Forest to prevent the dust pollutions. This makes the quality of the air emitted from the power plant’s stacks be according to the standards and regulations, as well as safety and environmental friendly.

Key Performance

Noise Pollution Management

- Appropriate design and install the machines and equipment that may cause the noise pollution including eplanning inspection and preventive maintenance. Plant bushy trees surrounding the power plant as green belt for buffering sound and wind that help to control noise level within the standards and regulations.

- Appropriate design and install the machines and equipment that may cause the noise pollution including eplanning inspection and preventive maintenance. Plant bushy trees surrounding the power plant as green belt for buffering sound and wind that help to control noise level within the standards and regulations. Designate 3 check-points for measuring the noise level; the sources of noise in the power plant, the control room of the power plant and the boundaries of the power plant. The noises are controlled within the standards and regulations, with routine measuring the noise level in every 3 months. Provide ear muffs for employees to wear when working in areas with noise level exceeding 80 Decibels. Employees are required to wear the ear muffs when working in that areas which warning signs were installed to remind them of this regulation.

- Provide ear muffs for employees to wear when working in areas with noise level exceeding 80 Decibels. Employees are required to wear the ear muffs when working in that areas which warning signs were installed to remind them of this regulation.

Waste Management

Ratch Pathana Group is dedicated to manage waste according to the legal standards and the policies of each power plant. Wastes are divided into two categories: hazardous waste and non-hazardous waste. The company’s waste management practices are as followings :

- Hazardous wastes are those that can be harmful to the environment, such as transformer oil, lubricants and chemical containers. These wastes are disposed according to the approved procedures to the agencies authorized by the Department of Industrial Works.

- Non-hazardous wastes are general wastes such as leftovers, wood, paper, wires, plastic bags, and constructionmaterials. These wastes are classified before disposing to bury according to the standards and regulations or appropriately recycling. The waste bank project was established to purchase recyclable wastes from employees in order to foster employees to utilize resources effectively.

เป้าหมายการลดของเสียอันตราย ปี 2566

2023 Performance

- Reduce

- Reuse

- Recycle

- Repair

- Reject

Performance table of the Environmental Waste Bank Project of 2023 Summarize the amount of waste and the amount of greenhouse gases that can be reduced from waste sorting for recycling

| Type | Volume (Kg) | CO2 Reduction**(kgCO2e) |

|---|---|---|

| Paper | 1,600 | 790.40 |

| Plastic | 341.60 | 296.85 |

| Metal | 18,198 | 20,727.52 |

| Glass | 233 | 173.35 |

| Aluminum | 13.10 | 44.23 |

| Total | 20,386 | 22,032.35 |

**Low Emission Support Scheme: LESS (http://ghgreduction.tgo.or.th/)

Water Related Risks

Water is an essential resource in electricity generation. As climate change increases water risks, either drought or food, this presents a challenge for new and existing power plants. In 2024, Ratch Pathana Energy prepared the water risk assessment process as part of the ESMS, using it as a decision-making tool and the basis for control or management measures to minimize risks. The assessment process will be deployed in 2025 onwards.

Measures to tackle water shortage

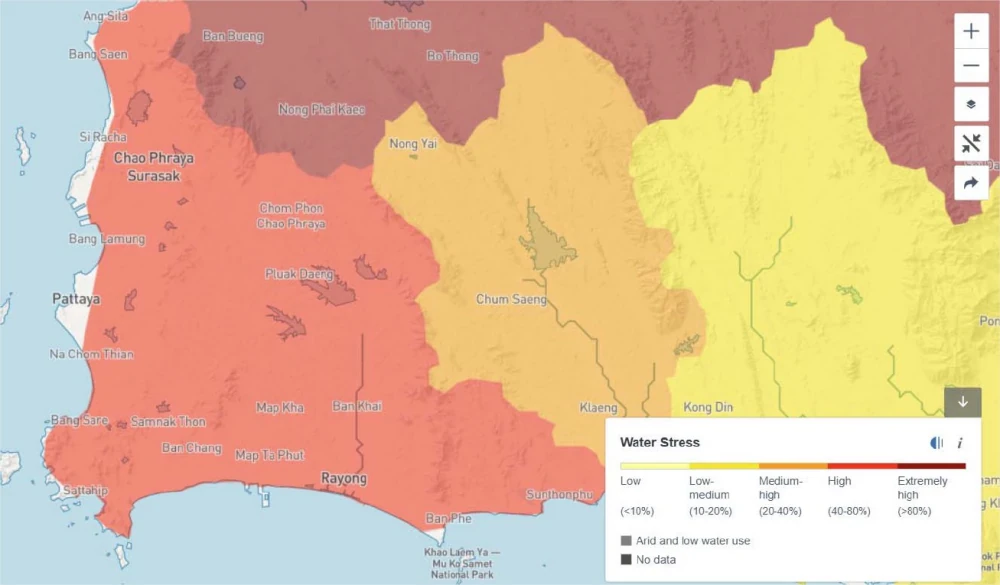

Operating power plants have assessed water risks from shortage based on the criteria of Water Risk Filter (WWF) and World’s Resources Institute (WRI) Aqueduct. Taken into account are legal requirements, financial aspects, raw water volume, water quality, utilization balance and relevant stakeholders. The results are used as the basis for water management planning.

Water stress assessment and production management

There are 3 sources of water for Ratch Pathana Energy Power Plant are Nong Kho Reservoir Dok Krai Reservoir and Bang Phra Reservoir.

In 2023, the Bang Phra Reservoir is primary source (0.00342% of 100% Reservoir) and the Nong Kho Reservoir and the Dok Krai Reservoir are second source of Ratch Pathana Energy were found to have high water stress level (at 40-80%)

Power plants’ measures and approaches to tackle water risks

- Ratch Pathana Energy Power Plant in Chonburi Province used raw water from the Dok Krai Reservoir, the Nong Kho Reservoir and the Bang Phra Reservoir under 5-year and 10-year supply contracts, respectively.

- Each power plant required tap water producers to prepare secondary and emergency water sources in case of drought or water shortage, to ensure sufficient resources for power generation.

- Reserve ponds or secondary storage system were in place for at least 30 days of internal use.

- Water quality improvement systems were installed.

- Water cycles in the cooling system were maximized, to reduce water withdrawal.

- Water reuse cycles for internal use were optimized, e.g. reusing RO-treated water in the production process or using rainwater or treated wastewater in the production, cleaning and tree watering.

- Water pipelines were regularly inspected to prevent water leakage and loss.

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม ประจำปี 2564 ฉบับสมบูรณ์ 1/2

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม ประจำปี 2564 ฉบับสมบูรณ์ 2/2

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม ประจำปี 2566 ฉบับสมบูรณ์ 1/3

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม ประจำปี 2566 ฉบับสมบูรณ์ 2/3

รายงานการะเมินผลกระทบด้านสิ่งแวดล้อม ประจำปี 2566 ฉบับสมบูรณ์ 3/3

Climate Change

The company realizes and participates tackling climate change issue including promote GHG management in company policy that beneficial to the organization, sociality, and Thailand environment. GHG management committee is assigned to implement the target through the company intention by awareness of environment upon the sense of social responsilibity as “good environment beneficial to sociality.”

To improve energy efficiency

To apply eco-friendly clean energy

Carbon offset

- Energy Innovative: participate in renewable energy and GHG reduction project. For instance, International Renewable Enegry Certificate (IREC), Joint Crediting Mechanism, and Clean Development Mechanism (CDM)

- Joint Crediting Mechanism (JCM)

- Arrange in house activity under the topic of reducing GHG in organization. To participate in neighboring community, government sector, and partners to enlarge green area for carbon sink by replanting

International Renewable Energy Certificate (I-REC)

- The company has registered Internation Renewable Energy Certificate (IREC) purposing to transfer IREC to the organization who intend to consume electricity from renewable energy sources in company activities. The objective is to minimize global warming from GHG emission.

- In 2023, Shahcogen Group delivered Renewable Energy Certificate which equivalent 73,608 tons CO2eq that is one of responsibilities to reduce GHG emission.

Key Performance

Clean Development Mechanism Project (CDM) by Sahagreen Forest Biomass Power Plant

- Reduce greenhouse gas emissions by 27,000 tons of carbon dioxide equivalents per year

- Cumulative reduction in greenhouse gas emissions from 2014-2023

Key Performance

Waste Bank for Environment Year 2023

Key Performance

Energy Saving

Ratch Pathana Group focuses on the energy saving attempt. The policy was set to create awareness for energy saving among management and employees. The energy management committee is set to implement and monitor the activities such as doing reports of energy consumption, excursion trips, information announcement and activities with employees. The examples of activities are energy day, picture contest, energy saving motto selection and reduction of consumption campaign, etc.